Advanced Laser Engravings for Ultimate Anilox Roller Performance

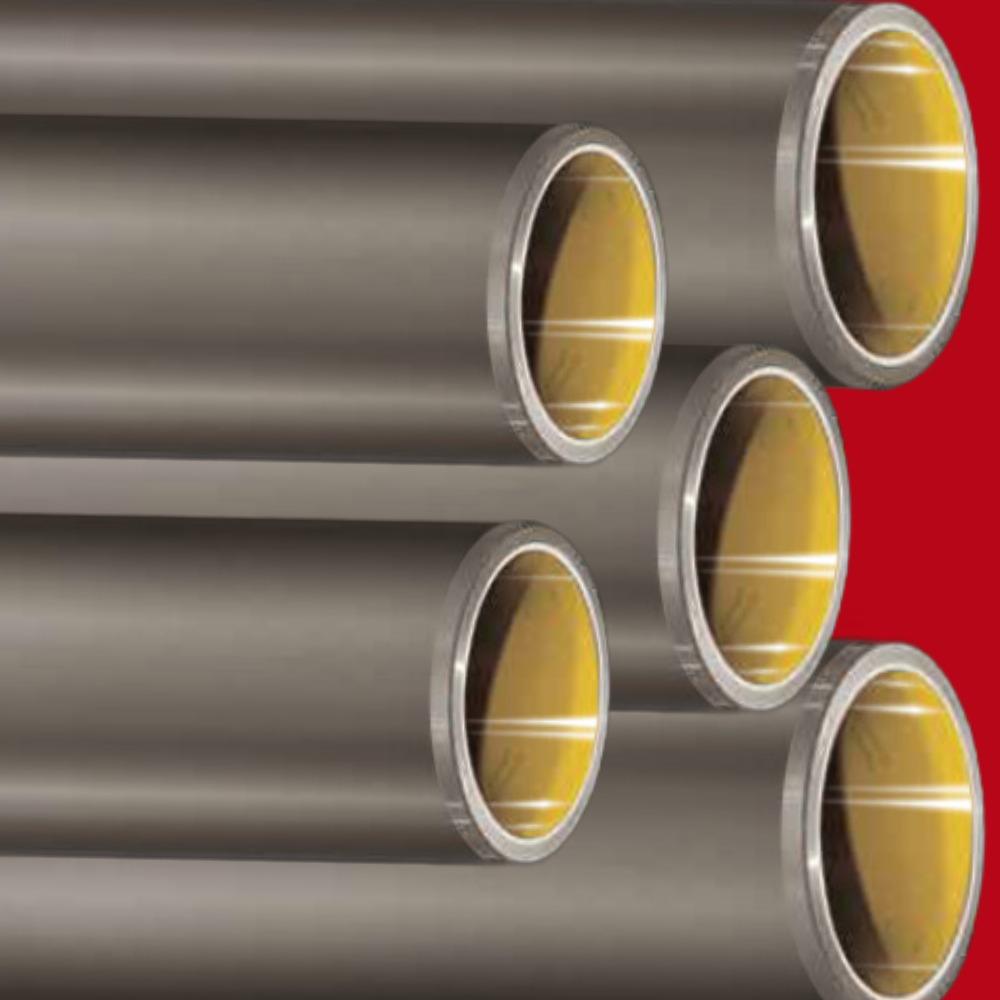

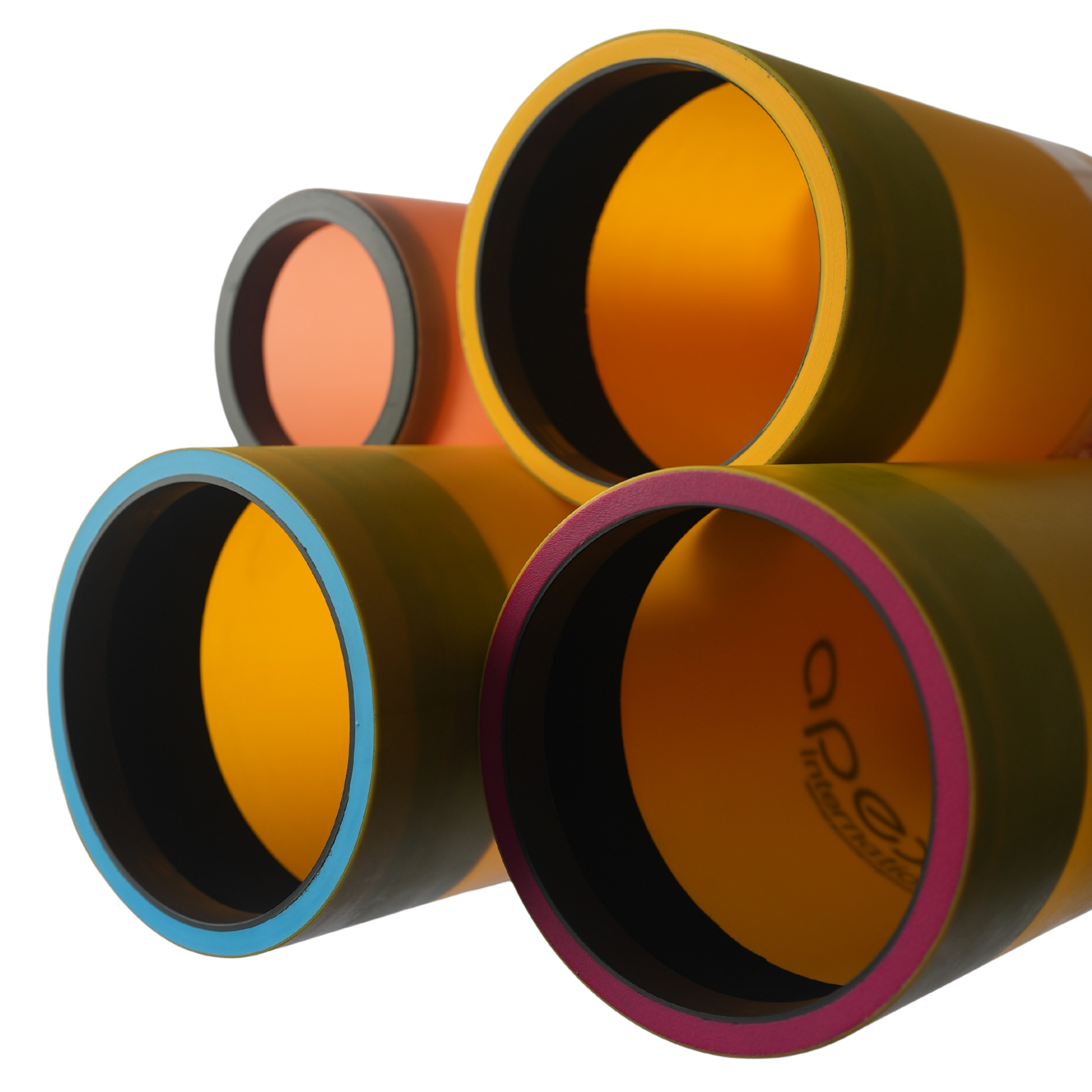

UltraCell engraving technology takes conventional laser engraved anilox roller solutions to the next level. The innovative cell geometries are engraved slower to create a melted / fused inner cell wall that requires no additional porosity masking sealants to be added to the coating – ensuring pure ceramic cells for optimum transfer. This controlled engraving process allows a more efficient ink / coating transfer, easier roll cleaning, and ultra resistance to anilox corrosion and scoring. With UltraCell’s super-dense, low-porosity, non-wetting ceramic coating, you can expect longer roll life, consistent cell volume and improved print and press performance overall. Take full advantage of your conventional engravings with this advanced anilox roller solution from Apex International.

ULTRACELL SPECIFICATIONS

MATERIAL

High-density, low-porosity Ceramic. This solid compact coating allows the UltraMelt engraving process to effectively melt and fuse any porosity closed.

WIDTHS

Up to 8 meters / 315 inches

DIAMETER

Up to 865 millimeters / 34 inches

LASER ENGRAVING

Apex’s UltraMelt laser-engraving process for more efficient ink / coating transfer, faster clean-up, super corrosion- and score-resistance.

APPLICATIONS

- Corrugated

- Flexo & Wide Web

- Label & Narrow Web

- Coating & Offset

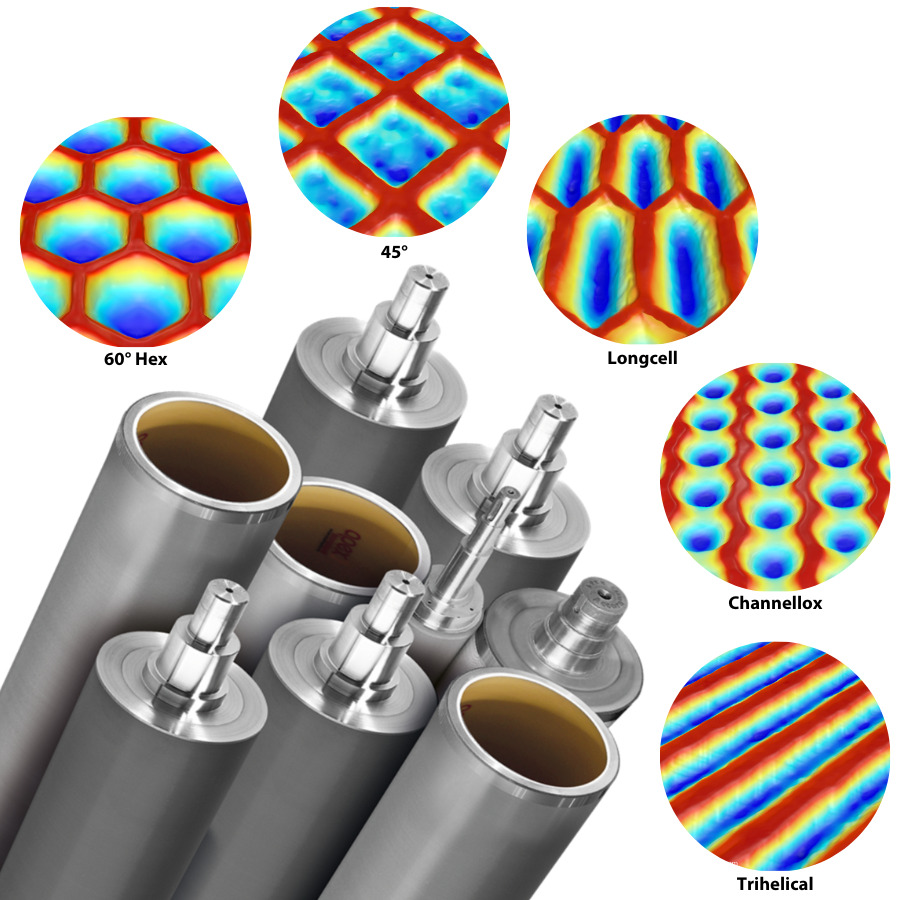

ADVANCED GEOMETRY

Wider and shallower profile geometry for greater ink release and easy clean up

- 60° Hex

- 45°

- Longcell

- Channellox

- TriHelical

- 60° Bottoms Up

- 45° Bottoms Up

- Custom engravings available

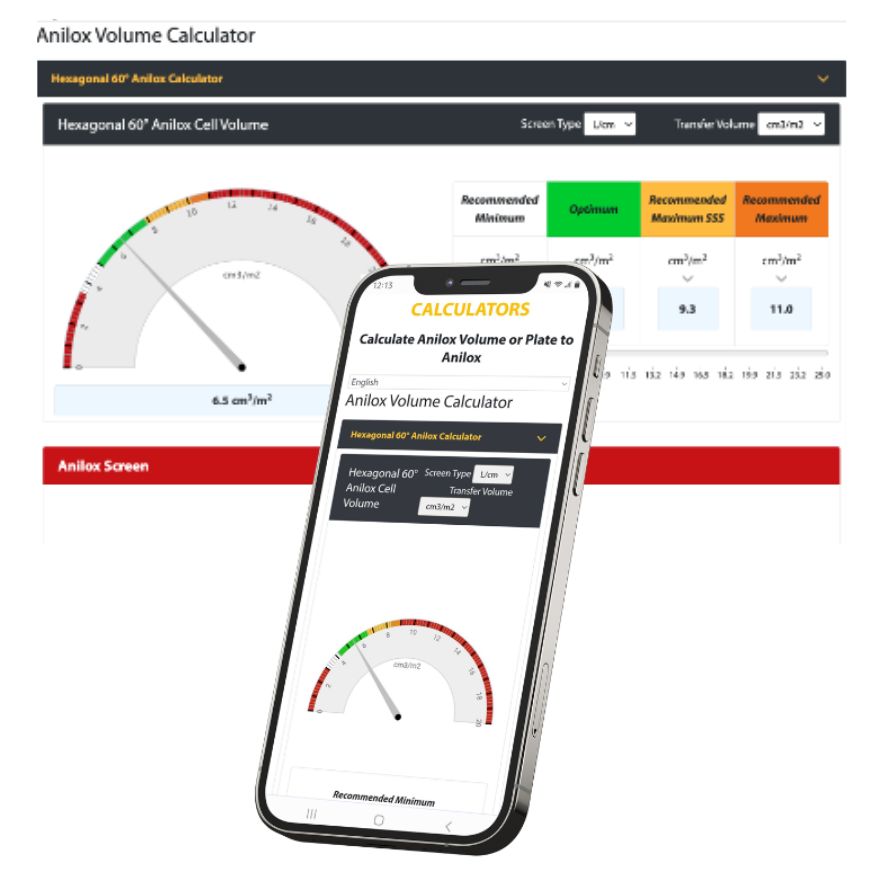

ENGRAVING SPECIFICATION

Choosing the right anilox roller volume and line screen for any job takes careful effort and time. Our calculator quickly removes the guesswork from anilox specification and helps you start printing immediately. Learn more about our calculators here.

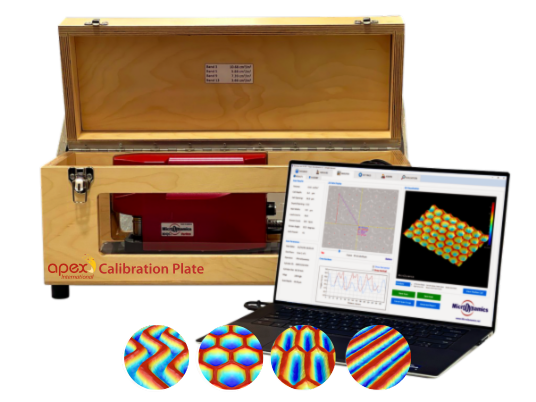

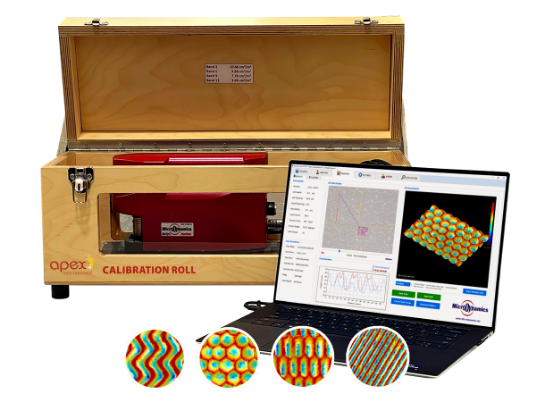

Introducing the First Accurate and Repeatable Volume Measurement System.

Endorsed by Apex.

Apex and MicroDynamics have partnered to create the only complete 3-in-1 measurement system in the world. Apex’s state-of-the-art software and calibration plates pair with the MicroDynamics Veritas© to provide you with the most comprehensive anilox roller inspection process the industry has to offer.

UltraCell Engraving Solutions

UltraCell’s advanced laser engraving technology offers a variety of competitive advantages:

Improve Transfer Quality

With a precision increase in cell width and decrease in cell depth coupled with its high-density, low-porosity ceramic coating, UltraCell increases ink release efficiency, maximizing ink/coating mileage and improving quality.

Achieve Ultimate Profitability

Printers and converters can reduce waste and improve their bottom line by using less ink, increasing press speed, and decreasing downtime for maintenance, cleaning, and troubleshooting.

Cell Engraving Precision & Quality Control

UltraCell anilox rollers and sleeves are available in a wide range of geometries that utilize Apex’s multi-phase laser engraving process. All engravings maintain cell volume precision and uniformity and are verified through rigorous laser interferometric cell-volume verification during Apex’s extensive quality control process.

Easier Maintenance & Extended Anilox Roller Life

With a shallower profile and stronger cell walls, UltraCell anilox rollers are easier to clean and maintain. The thick impermeable protective layer creates a score and corrosion resistant barrier extending roll life tremendously.