Precision Mechanical Anilox Engravings Built Tough

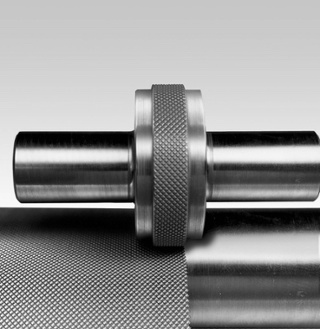

Since 1989, Apex International has manufactured mechanically engraved anilox cylinders with precision and durability. Avoiding accident-prone copper materials, Apex mechanically engraves your anilox cylinders using steel or hardened stainless steel materials using their innovative, custom engraving tools to engrave directly on the surface. With nickel and chrome plating options and a wide variety of cell geometries, Apex mechanically-engraved aniloxes are manufactured with the tightest T.I.R. and O.D. tolerances with even screening over the entire engraved surface.

MECHANICAL SPECIFICATIONS

MATERIAL

Steel or hardened stainless steel with optional nickel plating and/or galvanic hardened chrome plating and an anti-corrosion layer.

MECHANICAL ENGRAVING

High precision tools for uniform mechanical engravings directly on steel or stainless steel materials. Custom mechanical engraving tools available upon request.

APPLICATIONS

- Corrugated & Folding Carton

- Coating & Lamination

LINE SCREENS

8 l/cm (20 lpi) – 140 l/cm (360 lpi)

ADVANCED GEOMETRY

- 60° Hex

- 45°

- 30°

- Quadrangular

- Pyramid

- Hexagonal

- Tri-Helical

- Channellox or custom geometries available on request.

ENGRAVING SPECIFICATION

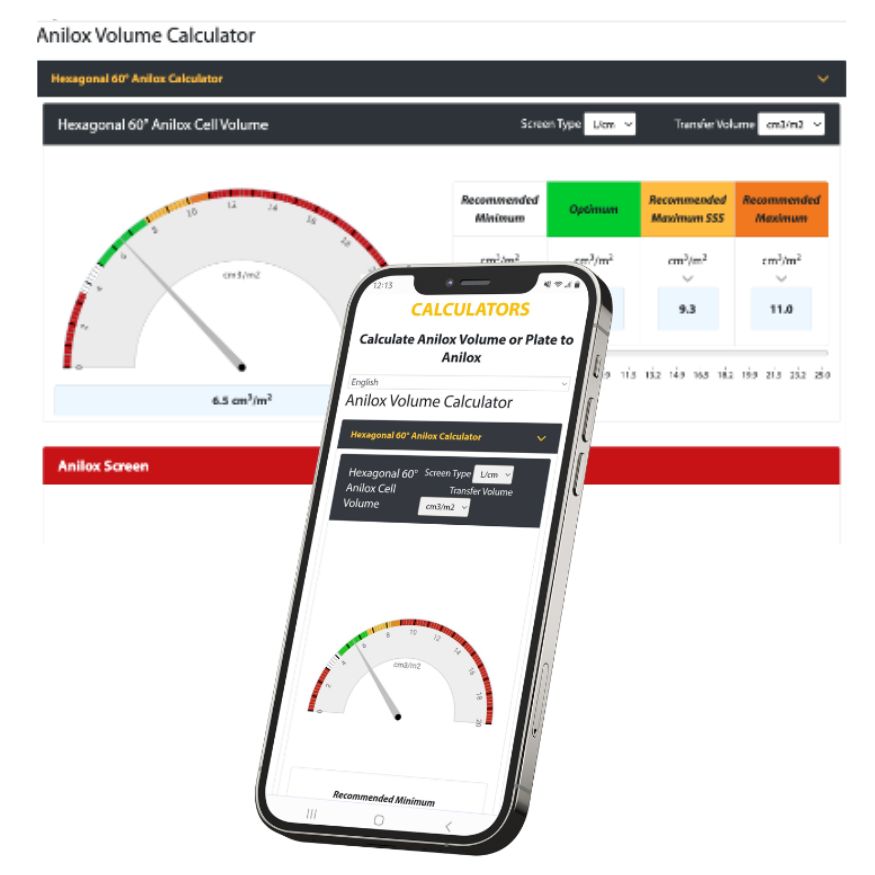

Choosing the right anilox volume and line screen for any job takes careful effort and time. Our calculator quickly removes the guesswork from anilox specification and helps you start printing immediately. Learn more about our calculators here.

Apex mechanically engraved anilox cylinders offer a variety of competitive advantages over competitor products:

Precision Engravings & Quality Control

Apex mechanically engraved anilox cylinders are available in a wide range of standard and custom geometries. All engravings maintain cell volume precision and uniformity and are verified through rigorous laser interferometric cell-volume verification during Apex’s extensive quality control process.

Robust, Durable Materials & Extended Roll Life

Utilizing steel and hardened stainless steel materials, instead of traditional soft copper compositions, increases roll longevity. Nickel plating and/or galvanic hardened chrome plating also extend roll life. All rolls are optimized with an anti-corrosion layer for increased resistance to scoring and abrasion.

Tightest T.I.R. & O.D. tolerances & Ultimate Print Quality

With the tightest T.I.R. and O.D. tolerances in the industry, you can ensure your mechanically engraved aniloxes meet OEM specifications and perform flawlessly with speed and quality throughout production.

Precision Engraving

High precision mechanical engraving tools are used to manufacture our rolls. Upon request, custom made mechanical engraving tools can be manufactured.