Multipurpose, adaptable, flexible.

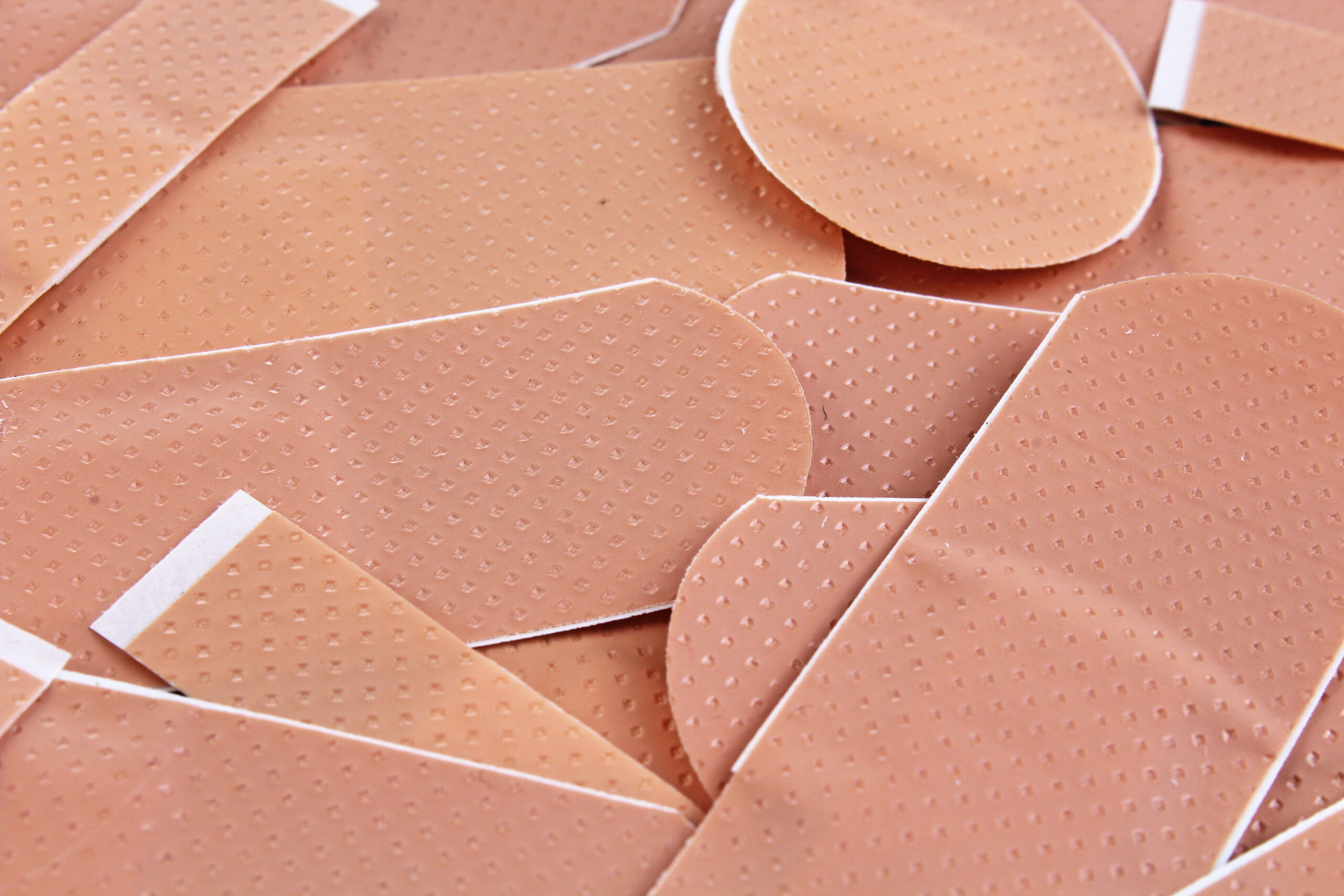

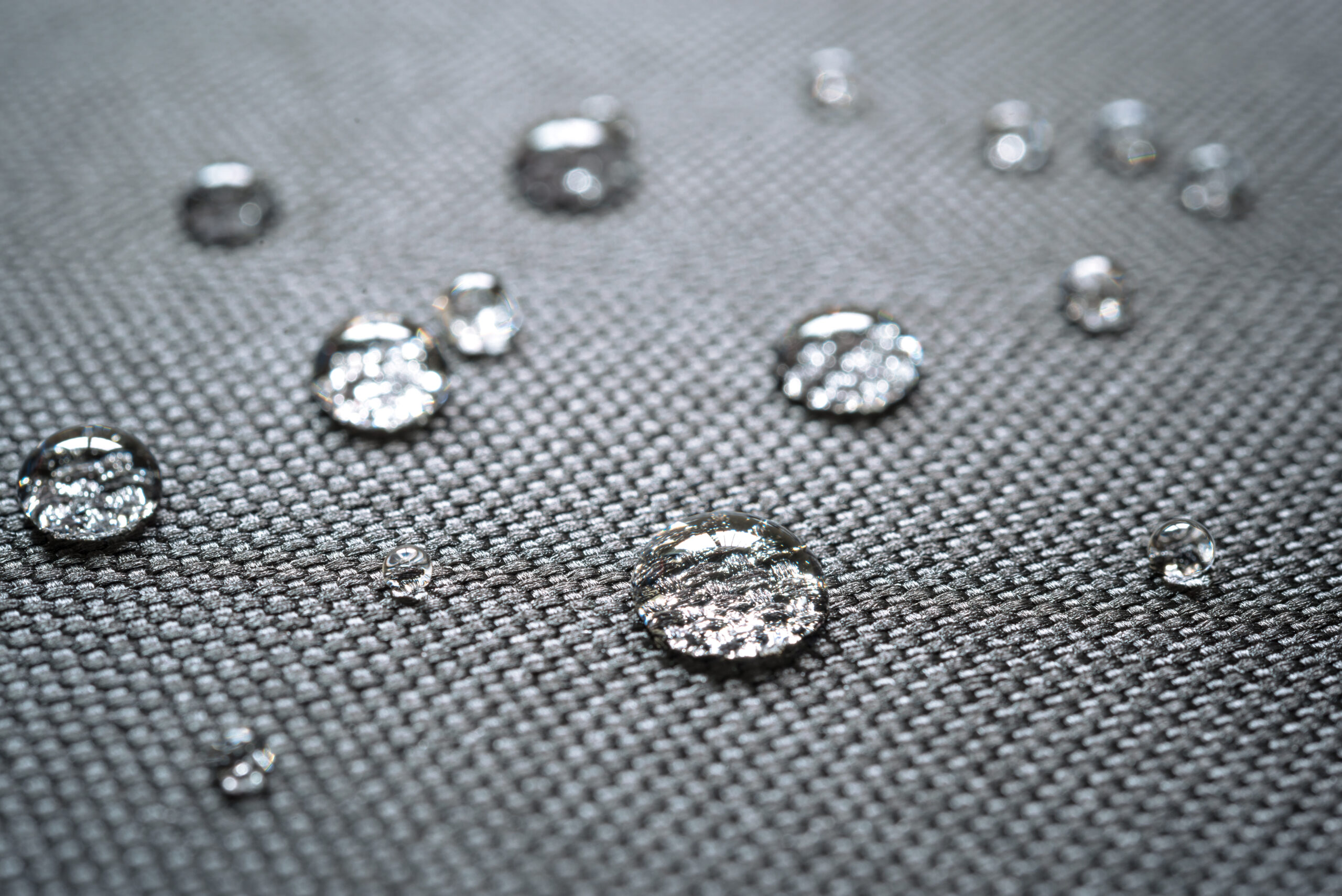

We have over 30 years of experience in designing and manufacturing precision embossing rollers and plates for a variety of purposes and industries. Our precision rollers enable the perfect transfer of adhesives, paints, and other substances onto a variety of materials. Working closely with our clients, we produce solutions for all uses including hotmelt and other glue applications, paint and lacquer coatings and siliconization. We create special requirement rollers with a variety of coverings, finishes and temperature specifications for reliable reproduction. Apex rollers are developed to suit the changing needs of our clients in demanding industries.

Precision Rollers For:

Adhesives

Lacquers

Fluids

Paints

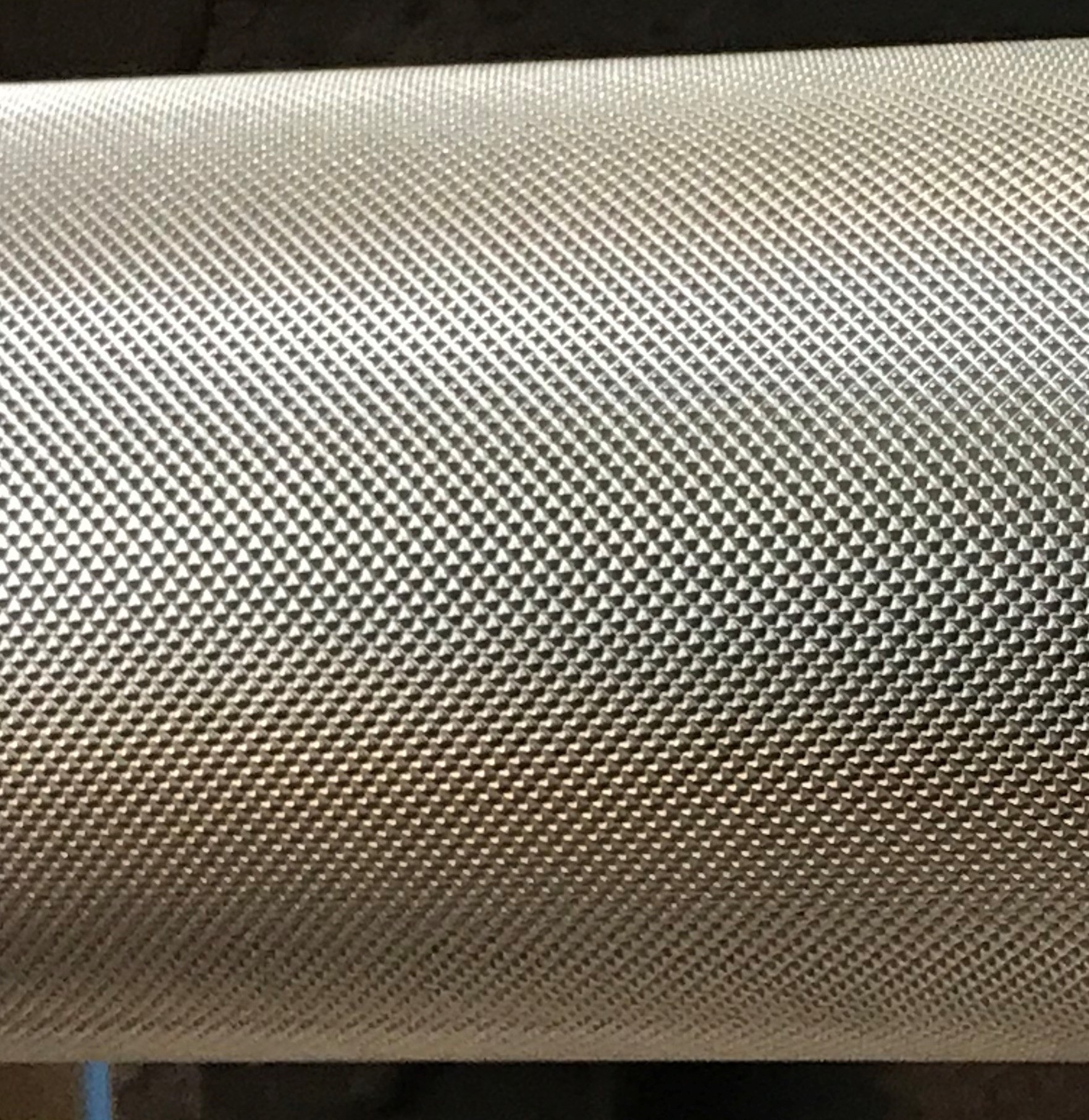

Precision engraving for the best results.

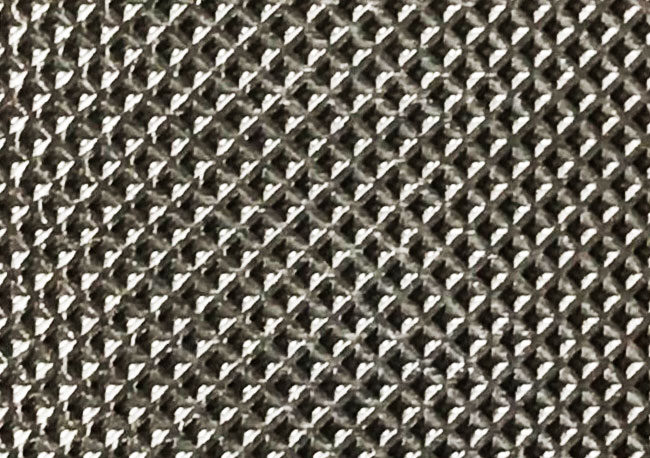

We manufacture our ceramic and chrome anilox to the highest possible standards using the latest engraving technology. This means that we reproduce designs with precise details, providing you with the best possible result every time. We use 2D and 3D visualization to assess the engraving parameters, so we can modify cell depth, web portion, pick-up volume, and the number of screens, according to the ever-evolving demands of our clients’ industries and products.

Explore Target Markets

Consultancy & Support

Communication is at the heart of what we do. We work closely with our customers to truly understand their needs before identifying the right solutions for their unique situations.

Technicality & Design

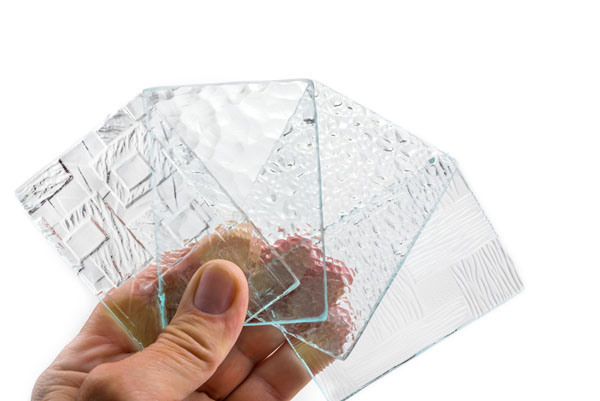

Your surface design is created by world-leading creative embossing designers, utilizing their unrivaled technical knowledge of the opportunities and demands of embossing rollers.

Process & Layouts

We utilize the very latest digital layout and 3D technology to support our clients in making the right decision for their embossing needs.

Roller & Steel Core Production

We have over 30 years of experience in manufacturing precision machined rollers for a variety of uses, including steel cores and sleeves.

Embossing Rollers & Sleeves

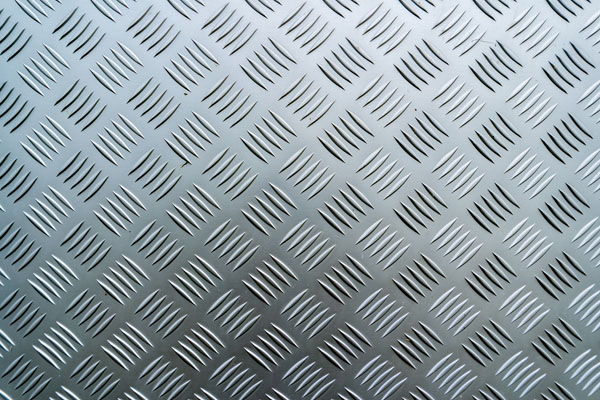

We produce tailor-made embossing rollers with the latest laser, etching and knurling technologies and techniques, effortlessly reproducing intricate details and patterns.

Pilot Plant

Our state-of-the-art pilot plant enables us to fully test new designs for quality before manufacturing, providing you with perfect results from the very first use.

Embossing Techniques

We use a variety of embossing techniques to produce different effects and meet the needs of our clients.

On-Site Assistance

We provide ongoing support to our clients in the form of onsite support, to ensure that once installed, the embossing rollers are working as they should.