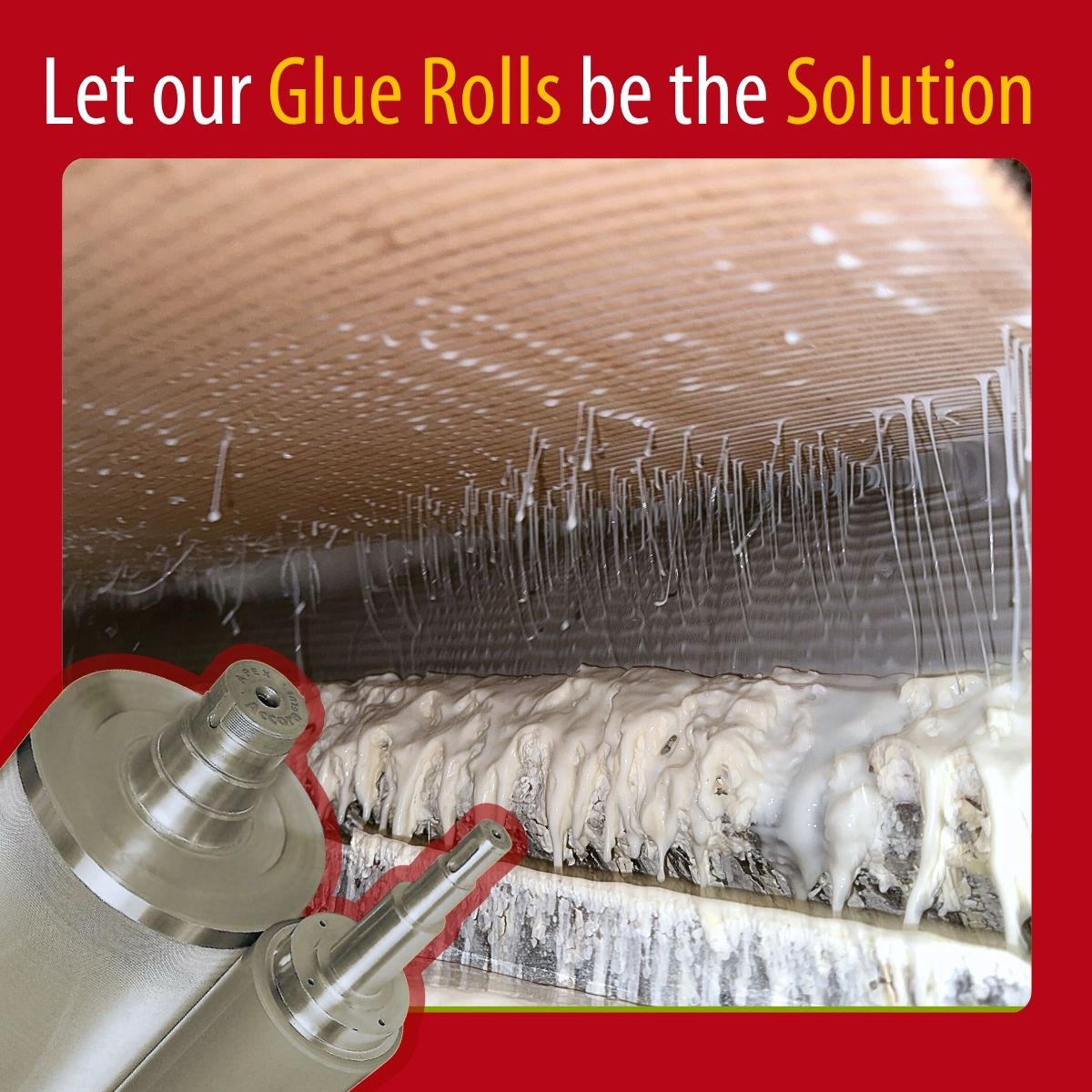

Have It All In One Corrugated Glue Set Solution

Exceptional Bonding, Drying, and Transport.

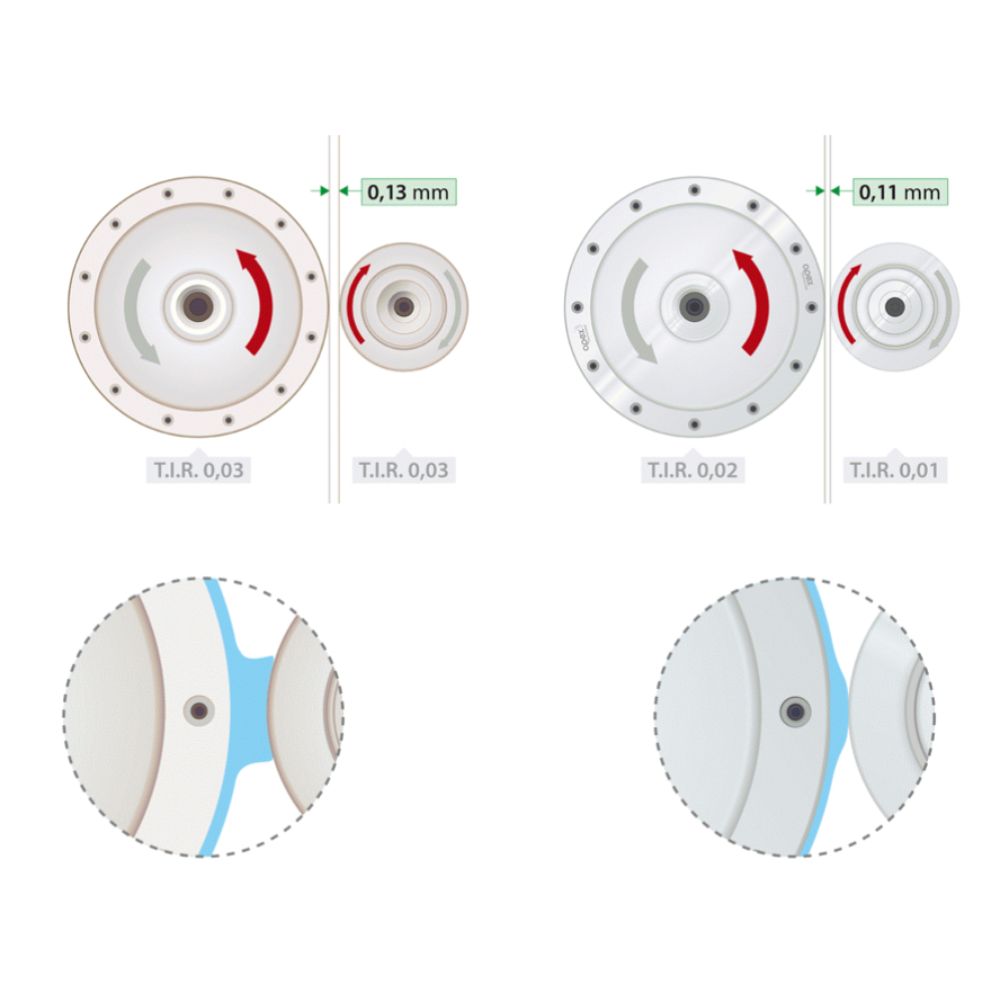

With Apex International, you can have it all with our Accora™ corrugated glue set solutions. Built using innovative manufacturing processes, Accora™ glue sets allow you to achieve higher precision and higher press speeds with less waste, steam/energy, rejections and defects. Accora™ is built tough, constructed using advanced metallurgy to resist scoring, damage and corrosion and increase roll life 2-3x longer than conventional chrome sets. Machined to the industry’s tightest T.I.R. and O.D. tolerances, Accora deliverables consistent glue starch metering, confidently specifying any gap down to 0.0178 mm / 0.0007″, from board to board. With increased savings, roll life, uptime, speed and profitability, Accora™ glue sets elevate precision and durability to new heights.

Built Tough. Built Smart. Built Right.

-

Exceptional Bonding, Drying, and Transport.

-

Reduce Energy (steam) consumption.

-

Reduction of Starch usage

-

Reduce or eliminate board warping.

-

Extended Roll Life

-

Proven Success: with over 10,000 smooth installations

Achieve more with less.

Using less starch, less water, less energy and less downtime, corrugators can achieve more with Accora™ corrugated glue set solutions. With a maximum T.I.R. of 0.0127 mm / 0.0005″, Accora rolls are created to your exact OEM specifications, typically exceeding accuracy requirements. This precision in manufacturing enables the most controlled, uniform and straight gap across the width of your glue set, meaning less starch is needed to achieve the required bond strength.

The reduction in the starch application means a reduction in board moisture, so turn down the heat and energy required for proper drying and turn up the profitability of your operations! With no flaking or corrosion, our proprietary super-finishing process means your rolls are ready to go, with no break-in period required.

Tighter gap control could save you a BOARD load of money!

By reducing your energy (specifically steam) usage, you can decrease costs substantially.

DON’T WAIT! Start exploring these savings possibilities today.

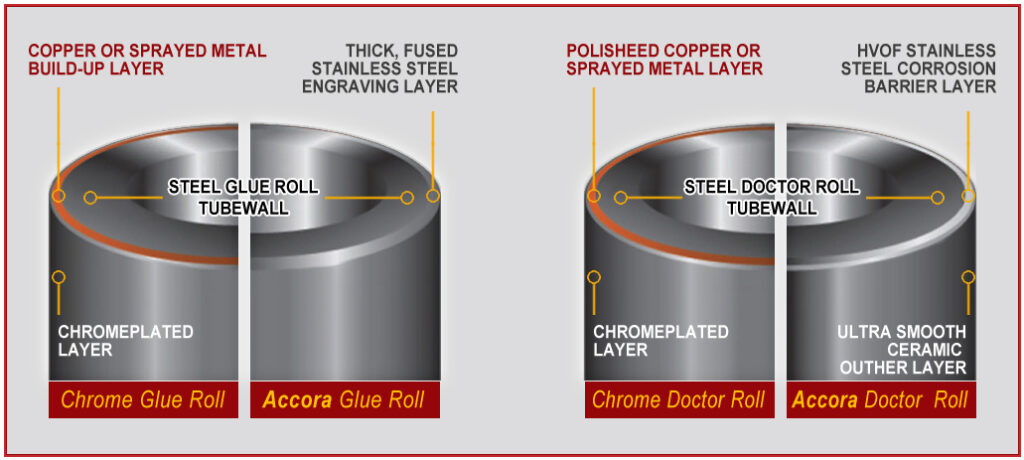

STAINLESS STEEL APPLICATOR ROLLS

MATERIAL

AST fusion manufacturing process provides a thick, double-clad layer of precision-engravable stainless steel. Once engraved, the stainless steel becomes a more compact and hardened structure which is stronger than chrome with lower surface porosity, providing superior starch release.

JOURNALS

All bearing surfaces, keyways, and threading requiring repair/refurbishing are turned, then double-clad in welded stainless steel (rather than less-durable sprayed metal), and finally machined.

TIR

Maximum TIR of 0.0127 mm / 0.0005″.

CERAMIC DOCTOR ROLLS

MATERIAL

Specially developed proprietary ceramic that has a mirror-like finish to exceed the process demands on the roller. A hydrophobic, super compact low porosity coating is applied at 0.254 mm / 0.01″ thickness per side over a stainless-steel corrosion barrier, eliminating corrosion and surface flaking problems with the added bonus of minimizing score lines.

JOURNALS

Journals refurbished to OEM specifications to ensure proper roll balance, keyways, thread and bearing surfaces.

TIR

Maximum TIR of 0.0127 mm / 0.0005″.

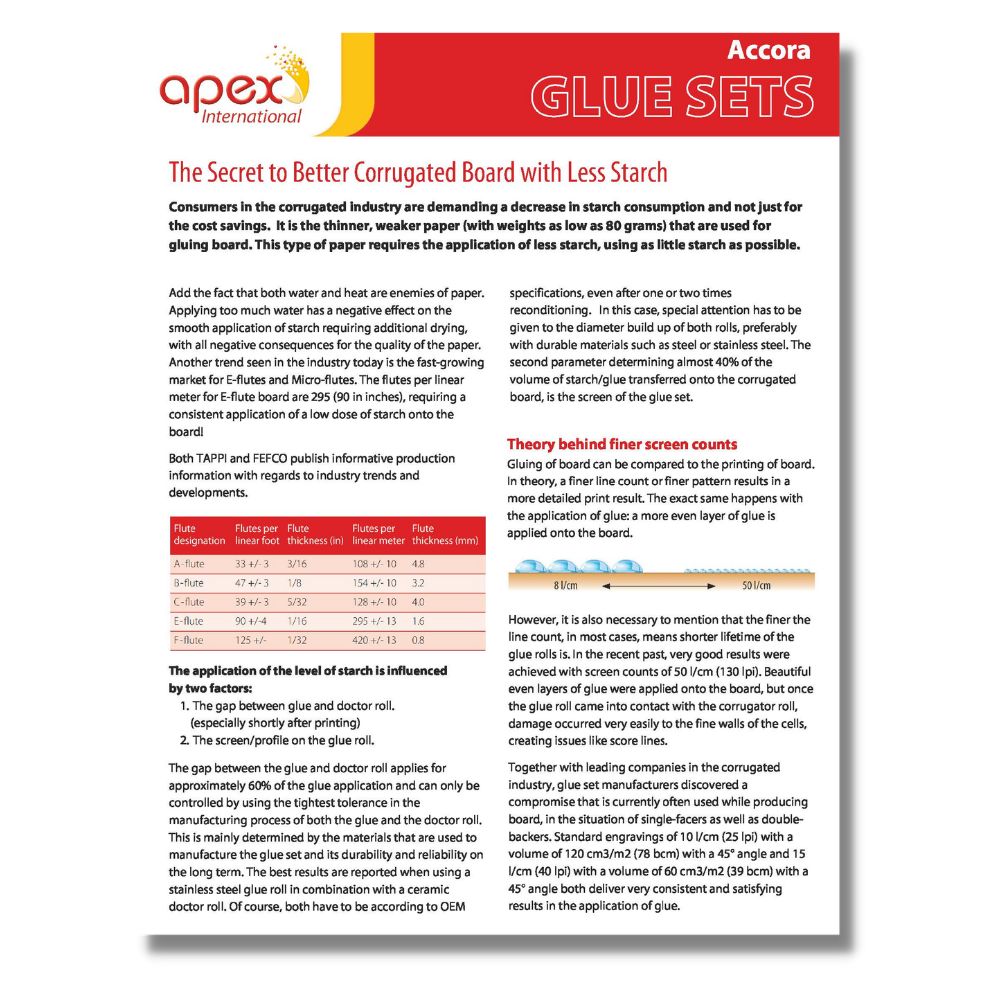

Easy on Starch, High on Quality

Enhance & Save in Your Production Processes with Accora Corrugated Glue Sets

Advanced Metallurgy & Materials

AST fusion manufacturing process provides a thick, double-clad layer of precision, engravable, and welded stainless steel, rather than less durable sprayed metal. Apex crafts a brand-new engraving mill for every single applicator roll, ensuring consistent engravings for each roll. Accora’s proprietary and rugged materials resist corrosion and scoring, lasting 2-3x longer than conventional chrome sets.

Achieve Gaps Down To 0.007"

Flat board is what Accora is designed to deliver. Proper bond strength across the board is realized through Accora’s precise TIR and OD tolerances. This precision in manufacturing enables you to achieve the most controlled, uniform, and straight gap across the width of your glue set, down to 0.0178 mm / 0.007″, reducing board defects and customer rejections significantly.

Highest Manufacturing Quality

Accora corrugated glue sets are manufactured with both the Outside Diameter (OD) and Total Indicated Runout (TIR) at a maximum TIR of 0.0127 mm / 0.0005”, exceeding OEM accuracy requirements. Rigorous QC testing ensure proper roll balance, plus flawless keyway, thread and bearing surface fitment for all new and refurbished rolls.

Increase Press Speed & Uptime

The proprietary super-finishing process of Accora means your rolls are ready for production with no rough engraving edges and no break-in period. The roll manufacturing quality generates a reduction in starch consumption and dry time, as well as consistently uniform metering, which allows corrugators to increase machine speed with minimal downtime for troubleshooting and adjustments.

Save on Starch, Water & Energy Consumption

The reduction in starch application equates to a reduction in moisture that is applied to the paper. With less moisture there is less heat and energy required to evaporate the excess moisture that is given to the paper during the gluing application. This reduced starch consumption and dry time enable the corrugator to reach top speeds profitably.

Reduce Board Defects Significantly

Installed in a well-calibrated corrugator tuned to OEM specs, Accora’s precise TIR and OD tolerances will eliminate and/or minimize common board defects such as warping, boarding, delamination, flashing, slinging and more.